What is Industrial Symbiosis?

The sharing of surplus resources, such as materials, energy or by-products between two or more companies. It can include the sharing of materials, logistical solutions, facilities and expertise.

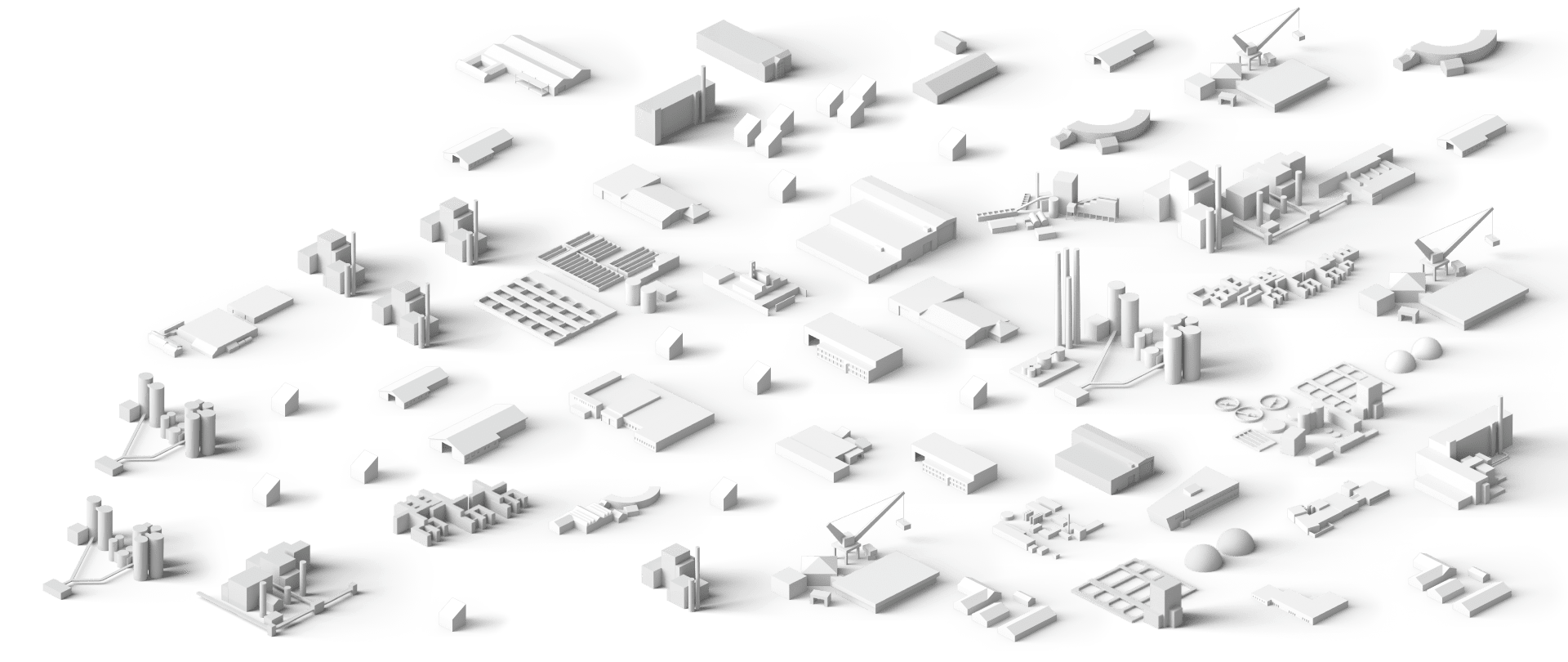

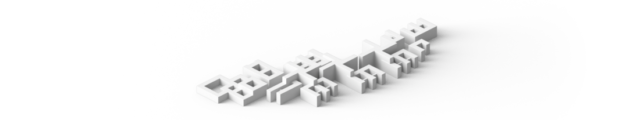

Nordjyske virksomheder har betragtet deres rest- og biprodukter som ressourcer i en længere årrække. På kortet ses et uddrag af både eksisterende udvekslinger mellem etablerede virksomheder og nyudviklede samarbejder, der vil kunne give gode og dokumenterede miljøeffekter. Symbiosekortet er i udvikling, og flere symbioser vil komme til. Hos Port of Aalborg R&D står vi klar til at sætte din virksomhed på symbiosekortet, hvad enten det er fordi du har en eksisterende symbiose kørende, eller du ønsker at komme i gang med en. Kontakt os, så guider vi dig til de rette samarbejdspartnere.

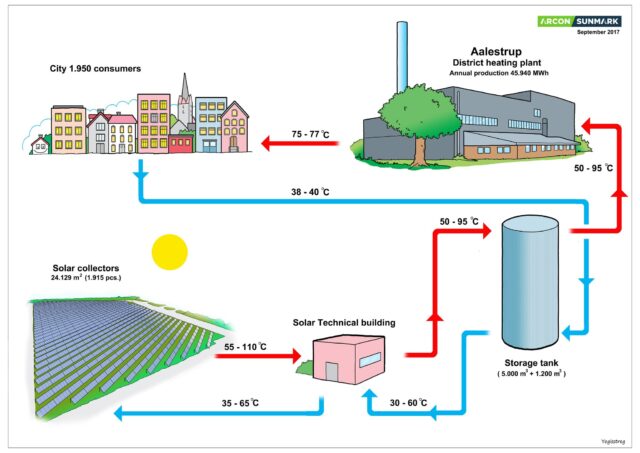

Aalestrup-Nørager Energi (AN-Energi) arbejder målrettet med at rykke barren for bæredygtig fjernvarme samtidigt med at forsyningssikkerheden af bæredygtig varme til forbrugeren sikres. I symbiosen mellem Nørager Mejeri og Aalestrup Varmeværk undersøgte vi, hvordan det vil kunne lade sig gøre at AN-Energi modtager overskudsvarme fra mejeriets produktion. Ved at udnytte overskudsvarmen til fjernvarme reduceres brugen af biobrændsel, der ellers ville indgå som en del af varmeproduktionen. Det har positiv miljøeffekt. Projektet forsøges startet i en nær fremtid, når økonomien hænger sammen. Vi arbejder stadig videre med samme tilgang til at finde bæredygtige måder at producere varmen på.

At være bæredygtig er den strategi, som også sikrer at vi leverer billig fjernvarme

Palle Jul Pedersen, driftslederAalestrup-Nørager Energi er et rigtig godt eksempel på en varmeforsyning, der arbejder proaktivt med bæredygtighed. Brændslet, der indgår i produktionen af varme, er bark og savsmuld. Et restprodukt, der ellers blot ville gå i forrådnelse. Den bæredygtige biomasse er blandt andet et spildprodukt fra lokale savværker.

Derudover kommer lidt over en femtedel af AN-Energis generede varme fra en CO2 neutral varmekilde – solfangere. Udover at være en CO2 neutral varmeforsyning i sig selv, er solfangerne tænkt i en større helhed. Der er nemlig indsat 58 får til at afgræsse græsarealet under og omkring solfangerne.

Læs mere her.

Aage Vestergaard Larsen A/S has both the capacity and expertise within plastics recycling to make them a significant potential partner in Aalborg Symbiosis. It is very advantageous in terms of traceability, ensuring that the plastic does not end up as waste elsewhere, but is actually recycled. Additionally, Aage Vestergaard Larsen A/S also produces high-quality pellets for moulding new plastic products from the material.

Although local recycling saves transport, it first and foremost ensures that we know what happens to the plastic. And that it is reused optimally!

Gitte Buk Larsen, Business Development & Marketing ManagerAage Vestergaard Larsen A/S is the Nordic region’s largest company within the recycling of high-quality plastic. The company invests in production and forms of production based on recycled plastic. The company focuses on the UN’s 17 Sustainable Development Goals, with a particular emphasis on promoting prolonged and sustainable economic growth. Moreover, efforts are being made to revitalise the Global Partnership for Sustainable Development and by extension, to bolster the resources for achieving the objectives.

Aage Vestergaard Larsen A/S’s vision is to create long-term values for stakeholders by making their innovative know-how about recycling plastic available to business partners. In addition, Aage Vestergaard Larsen A/S will develop innovative and sustainable solutions in a circular economy to ensure that waste becomes a valuable resource and global CO2 emissions are reduced.

The cement producer Aalborg Portland is the oldest link in the industrial symbiosis network in Aalborg. Over the years, Aalborg Portland has participated in several important symbioses as illustrated on the map.

In this symbiosis, Aalborg Portland receives purified sand from the Port of Aalborg. The sand is derived from the regular dredging of the Limfjord, which is necessary to maintain access for shipping in the fjord. Since sand, combined with lime, is the principle raw material in grey cement production, the sand is used in Aalborg Portland’s cement production. Prior to this collaboration, the purified sand was dumped into the sea. The quantities of purified sand vary over the year depending on weather conditions. In 2019 just over 150,000 tonnes of sand were recycled.

This is a two-way symbiosis, whereby Aalborg Portland delivers lime sludge to Nordjyllands Power Station and receive gypsum in return. Lime sludge is a by-product of cement production, generated at Aalborg Portland when lime is mined from the limestone quarry. The lime sludge is used at Nordjyllands Power Station for flue gas treatment. The flue gas treatment process generates gypsum of a sufficient quality to be used in cement production at Aalborg Portland.

Aalborg Portland is a key player in the energy symbiosis. Aalborg Portland currently supplies surplus heat to Aalborg Utilities, providing district heating for approx. 30,000 households in Aalborg Municipality. However, this figure is expected to increase to 50,0000 households in the future, a target that Aalborg Portland is working towards through a new supplementary agreement with Aalborg Utilities.

Aalborg Portland is also involved in a symbiosis with the wastewater treatment plants East and West. The wastewater plants have a number of residual products in the form of sludge and materials from screening (toilet paper, etc.). As part of the symbiosis, these residuals are processed at a sludge drying plant and then sent to Aalborg Portland to be used as fuel in cement production. Approximately 3,000 tonnes were recycled in 2019.

Although Aalborg Portland is part of a global group, all the company’s development activities are centred in Aalborg, where the company’s research and quality department is located. Development and production of cement products at Aalborg Portland is focused on socio-economic sustainability. Based on a holistic approach, the company contributes to the global achievement of the UN’s sustainable development goals, both economically, socially and environmentally.

Development towards sustainable production started in the 1970s, when energy efficiency came into focus. Since then, tremendous strides have been made through numerous initiatives involving alternative fuels, surplus heat for district heating, recycling of waste etc.

Today, sustainable production remains a key focal point for employment, technological development and exports. Aalborg Portland contributes to the UN-2030 agenda for sustainable development, and several of the associated 17 SDGs, as well as the COP21 Paris global climate agreement.

As part of the Sustainable Synergies project, APSV has been exploring opportunities for recycling Aluzinc offcuts from NB Ventilation for use in the company’s production of cladding. The symbiosis between APSV and NB Ventilation is a classic exchange of materials, by which the scrap and waste from one production can be reused by another company. The material is galvanised steel plate, which is corrosion resistant and durable. NB Ventilation annually discards a significant quantity of Aluzinc scrap. Supply of the residual quantities negates the purchase of new Aluzinc sheets, as well as the transport from China. Moreover, APSV also saves resources because their residual product no longer has to be remelted. Transport of material for remelting is avoided, in which the corrosion-resistant alloy is also lost.

”… man sparer på ressourcerne, fordi det giver mening.”

Peter Le Dous, ejerAalborg Profil- & Smedeværksted offers customized solutions and execution of tasks within the traditional blacksmith and plumbing profession. The tasks comprise everything from small flashings to entire facades, classic fabrication and assembly work. Aalborg Profil- og Smedeværksted focuses on good old-fashioned common sense. Usable cardboard boxes are stored and smaller parts are sent to customers in them. Waste is used optimally and creative thinking is applied to utilize all residual materials and parts. As a small company, it is possible to think of solutions that avail of the resources at hand, thus ensuring minimal waste.

Aalborg Recycling is a key enterprise in two symbioses around plastic recycling. One is an ambitious collection and processing of agricultural foil. This is quite a challenging process, as the plastic resource is mixed with soil and spread out geographically. Aalborg Recycling is establishing a production plant for this process. The potential environmental benefit of this form of recycling is enormous, as huge quantities of agricultural foil are currently not being recycled.

In the other symbiosis, plastic sheets are collected at Aalborg Recycling with a view to becoming new plastic of similarly high quality. The quantities of plastic sheets are so small that strong collaboration between companies is needed for it to be feasible. Now they shall be collected with a view to recycling them.

Agricultural plastics are not handled well enough today. We will create a business based on the recycling of the plastic in North Jutland in collaboration with a range of companies.

Bernt Pedersen, Aalborg Recycling AfdelingschefAalborg Recycling is one of the country’s leading companies in the recycling of iron and metal scrap, demolition, cutting work and cutting tasks with recycling as its primary business area. Scrap is a key business area that requires strong relationships with many companies, established logistics and optimal possibilities for collecting other fractions, e.g. utilising unladen journeys. This benefits both the environment and the companies of North Jutland.

Aalborg Utilities is a key enterprise in energy symbiosis, whereby surplus heat from several local companies accounts for an increasing proportion of the district heating. The use of surplus heat that would otherwise be wasted reduces primary energy consumption in heat production and affords economic and environmental benefits. Aalborg Utilities is continuously assessing, which companies with surplus heat can participate and remains in ongoing dialogue with potential contributors. Utilization of surplus heat is one of several methods that Aalborg Utilities employs to reduce the use of fossil fuels, enabling district heating supply to be derived from completely green energy by 2028.

However, Aalborg Utilities’ role in Industrial Symbiosis Aalborg extends beyond collaboration with local companies that contribute to greener district heating. Aalborg Utilities also collaborates with Aalborg Portland and the new University Hospital in Aalborg to provide a sustainable alternative to traditional cooling systems. District cooling shall avail of the constantly cold water of Aalborg Portland’s limestone quarry to cool the hospital buildings. Cooling of the hospital is an important step in developing comprehensive district cooling systems in Aalborg. More and more companies in Aalborg are expected to receive district cooling in the future.

” Nordjyllands Power Station”, one of the companies in Aalborg Utilities, is involved in numerous symbioses that extend beyond district heating and cooling.

Such symbioses include fly ash (a residual of incineration at the power plant) used by various companies in the area. Instead of dispatching this by-product to landfill, it is used in Aalborg Portland’s cement production. The asphalt manufacturer Colas Denmark also receives fly ash from the power plant in Aalborg. E-mineral is the company responsible for the nationwide trade of the by-product from power plants. In another two-way symbiosis, Nordjyllands Power Plant receives lime sludge from Aalborg Portland and delivers gypsum back to them. Lime sludge is a by-product of cement production generated by Aalborg Portland’s mining of lime from their limestone quarry. The lime sludge is used at Nordjyllands Power Station for flue gas treatment. The flue gas treatment process generates gypsum of a sufficient quality to be used in cement production at Aalborg Portland.

Finally, Nordjyllands Power Station is also involved in a symbiosis with the agricultural sector in the area. Previously, surplus water from the fields was pumped into the Limfjord. Now around 120,000 m3 of water is collected and transported through a complex pipe system to Nordjyllands Power Station, where it is used in the gypsum production process. Consequently, the surplus water replaces groundwater in the process.

Aalborg Utilities is also engaged in a number of other symbioses within other supply industries. Return to the map to read more.

Holistic thinking and sector connections, which is precisely the essence of Environment++, are absolutely crucial for us to reach the goal of a sustainable restructuring of the energy systems in Aalborg and Denmark in general.

Jesper Møller Larsen, Supply Manager, Aalborg Utilities.Aalborg Utilities comprises a number of utility companies owned by Aalborg Municipality. These companies supply customers with district heating, cooling, gas and water. Additionally, they divert wastewater, collect waste and provide energy advice. Aalborg Utilities contributes to sustainable development in numerous ways: Transitioning the energy system to renewable energy, promoting the circular economy, tackling climate change and securing continued access to clean water and sanitation.

Aalborg Utilities and the Environment and Energy Administration have implemented environmental and workplace management systems in accordance with ISO 14001 Environmental Management Systems and OHSAS 18001 Work Environment Management Systems under joint certification.

Aalborg Utilities’ vision from 2020 is to ensure that all energy supply is based on renewable energy sources, and that wastewater and waste are handled using the best available technology. The vision is also to conserve and protect the earth’s resources, limit and handle waste in closed circuits, and ensure that the supply of drinking water is based on clean groundwater. Aalborg Utilities’ goal of delivering sustainable services also falls under the auspices of Green Hub Denmark, by which Aalborg Utilities will enter into partnerships for the large-scale development and testing of the green solutions of the future.

Wastewater Treatment Plant East together with Wastewater Treatment Plant West engages in symbiosis with Aalborg Portland, Reno Nord and Kingo Recycling respectively. The wastewater treatment plants in Aalborg East and West have numerous residual products in the form of dried sludge, screened waste (cloths, bandages, condoms, etc.) and sand. The combined surplus sludge from both plants is fed into the plants’ digesters to be used in biogas production. The digested sludge is subsequently dewatered and delivered to the sludge drying plant to be dried and become biogranulate. The biogranulate is sent to Aalborg Portland, where it is utilized as biofuel, substituting coal and petroleum coke. It also substitutes raw materials in cement production via the ash fraction. Aalborg Utilities supplies around 3.3 to 4 tonnes of biogranulate to Aalborg Portland annually. Screened waste is delivered to Reno Nord, where it is incinerated to produce district heating. The sand is collected by Kingo Recycling, sanitised, and subsequently used in noise barriers.

Both wastewater treatment plants in Aalborg are classified as MBNDK treatment plants, making the plants among the most advanced in Denmark. The wastewater undergoes a mechanical, biological and chemical treatment, and Wastewater Treatment Plant East has the capacity to treat wastewater from 96,000 population equivalent. After treatment, the wastewater from the plant is discharged into the Limfjord.

Wastewater Treatment Plant West and Wastewater Treatment Plant East are engaged in a joint symbiosis with both Aalborg Portland, Reno Nord and Kingo Recycling. Residual products from the wastewater treatment plants in Aalborg comprise dried sludge, screened materials (cloths, bandages, condoms, etc.) and sand. Biogas is produced from the total surplus sludge production from both plants, which is fed to the plants’ digesters when it is separated from the wastewater. The digested sludge is subsequently dewatered and driven to the sludge drying plant, where it is dried and turned into biogranules. At Aalborg Portland, the biogranulate substitutes coal and petroleum coke as fuel. It also substitutes raw materials in cement production when it becomes part of the ash fraction after firing. Aalborg Utilities supplies around 3.3 to 4 tonnes of biogranulate to Aalborg Portland annually. Screened waste is incinerated at Reno Nord to become part of the district heating production. Kingo Recycling collects the sand and sanitises it for use in noise barriers.

Both Wastewater Treatment Plant West and Wastewater Treatment Plant East are classified as MBNDK treatment plants. This means that the wastewater undergoes a mechanical, biological and chemical treatment, making the plants among the most advanced in Denmark. Wastewater Treatment Plant West has the capacity to treat wastewater from 265,000 population equivalent. After the wastewater has been treated at the plant, it is discharged into the Limfjord.

Aarup Kloak og Entreprenør ApS er én ud af fire lokale og mindre entreprenørvirksomheder, der står for hovedparten af nedrivning af saneringsmodne ejendomme i Thisted Kommune. I samarbejdet om udsorteringssymbiosen mellem de fire entreprenører; Allan Thomsen, Koldby entreprenøren, Aarup Kloak og Bøgelund Maskinstation kommer det til udtryk, at hver for sig kan entreprenørerne ikke skabe kritisk masse i affaldsfraktionerne såsom mursten, beton, træ og tegl, så de kan afsættes til attraktive markedspriser og samtidig være bæredygtige. En stor del af materialerne er derfor før symbiosen anvendt til forbrænding eller deponi. Derfor har symbiosen f.eks. handlet om at skaffe fælles viden om markedet for affald og om at finde fælles fodslag. Helt konkret arbejder vi på at finde en fysisk lokalitet, hvor vi kan samle affaldsressourcerne inden videresalg. På denne måde sikres det, at ressourcerne håndteres på bæredygtig vis, både økonomisk, miljømæssigt og socialt forsvarligt.

Saneringsmodne huse genopstår som bålhytte

Udover symbiosen med udsorteringspladsen samarbejder de fire entreprenører også med Borgerforeningen i Villerslev. Her arbejder de benhårdt på at indsamle gode restmaterialer i form af mursten og træ fra nedrivningshuse til opførsel af byens nye bålhytte. Når hytten i Villerslev står færdig, vil det være et klokkeklart eksempel på en bæredygtig håndtering, hvor materialerne får et efterliv i en rekreativ park. Ydermere er det et vellykket og lokalt eksempel på, at det giver mening at tænke den grønne omstilling ind i byggeriet.

Det har altid været sund fornuft at forsøge at undgå at affaldet – eller ressourcerne – fra de nedrevne ejendomme ender i deponi. Det vil som minimum sige omdannelse til energi på forbrændingen. Entreprenørerne arbejder derfor hårdt på at få restressourcerne endnu højere op i affaldshierarkiet (forebyggelse, genbrug og genanvendelse). Igennem et samarbejde bliver det muligt at få flere affaldsressourcer højere op i hierarkiet alene af den årsag, at man nu kan indsamle store mængder af flere fraktioner, så det bliver interessant for en aftager at købe det.

Se TV2 MidtVests reportage om symbiosen- ’Konkurrenter i grønt samarbejde’, her.

AB Cool has had the first symbiotic activities in the network in connection with the use of their by-product ethylene glycol. It is a by-product from the manufacturing of refrigeration systems at the company. AB Cool can supply this by-product to the Aalborg Utilities wastewater treatment plant, where it is used as food for bacteria in the process of wastewater purification. AB Cool supplied approx. 800 litres to Aalborg Water in 2016.

AB Cool has more than 40 years experience in refrigeration, freezing and air conditioning systems. The company has incorporated several different initiatives to become more sustainable. AB Cool makes extensive use of waste sorting. Consequently, the company takes great pride in disposing of waste in a safe and climate-friendly way.

Moreover, AB Cool also focuses on minimising waste and actively seeks to utilise systems and facilities for as long as possible. This is especially reflected in their leasing of used refrigeration systems, extending the life of the systems. The company’s manufacturing of the refrigeration units generates the by-product ethylene glycol, which by agreement is delivered to Aalborg Wastewater Treatment Plant West, which employs this by-product in their water purification process.

Apart from waste management, AB Cool also focuses on minimising energy consumption. The company has had LED lighting systems installed in their production facilities, and procured solar cells, which will help minimise energy consumption while providing a more sustainable energy source.

Various agricultural companies in North Jutland are going to collaborate in an ambitious collection and processing of agricultural foil. It is a challenging initiative, as the plastic resource is geographically spread throughout the region and mixed with soil. The waste management company Aalborg Recycling is establishing a production plant for processing the material. The potential environmental benefit of this form of recycling is enormous, as huge quantities of agricultural foil are currently not being recycled.

Alfa Laval, in collaboration with Aalborg Utilities, engages in energy symbiosis in Aalborg. In the symbiosis, surplus heat from Alfa Laval’s production is supplied to the Aalborg Utilities district heating network. In general, the industrial sector plays a major role in the development of a sustainable heat supply in Aalborg, whereby conventional heat sources are being replaced by greener initiatives. The company increased its share of surplus heat supplied to the network in 2020.

Alfa Laval is one of the world’s leading suppliers within heat transfer, centrifugal separation and fluid handling.

Alfa Laval’s relatively new office building on Gasværksvej in Aalborg has received a DGNB silver certificate. DGNB certification is a guarantee that a building is sustainable and that sustainability is considered in all aspects of the building. This also means that all the building materials selected and processes must be traceable back to the manufacturer and be of sustainable materials. The office building has i.a. a low energy rating, as solar cells and solar shading are deployed to reduce energy consumption.

Alfa Laval in Aalborg develops, delivers and services boilers, burners, heat exchangers and inert gas burners for ships and industries worldwide. In recent years, their Aalborg department has also had an increasing focus on the development of green technologies for shipping, such as scrubber solutions for cleaning sulphur gases from funnels on ships. In addition to the sustainable initiatives in Aalborg, the company has many more sustainable initiatives and enterprises on a global level.

Allan Thomsen er én ud af fire lokale og mindre entreprenørvirksomheder, der står for hovedparten af nedrivning af saneringsmodne ejendomme i Thisted Kommune. I samarbejdet om udsorteringssymbiosen mellem de fire entreprenører; Allan Thomsen, Koldby entreprenøren, Aarup Kloak og Bøgelund Maskinstation kommer det til udtryk hver for sig kan entreprenørerne ikke skabe kritisk masse i affaldsfraktionerne såsom mursten, beton, træ og tegl, så de kan afsættes til attraktive markedspriser og samtidig være bæredygtige. En stor del af materialerne er derfor før symbiosen anvendt til forbrænding eller deponi. Derfor har symbiosen f.eks. handlet om at skaffe fælles viden om markedet for affald og om at finde fælles fodslag. Helt konkret arbejder vi på at finde en fysisk lokalitet, hvor vi kan samle affaldsressourcerne inden videresalg. På denne måde sikres det at ressourcerne håndteres på bæredygtig vis både økonomisk, miljømæssigt og socialt forsvarligt.

Saneringsmodne huse genopstår som bålhytte

Udover symbiosen med udsorteringspladsen samarbejder de fire entreprenører også med Borgerforeningen i Villerslev. Her arbejder de benhårdt på at indsamle gode restmaterialer i form af mursten og træ fra nedrivningshuse til opførsel af byens nye bålhytte. Når hytten i Villerslev står færdig, vil det være et klokkeklart eksempel på en bæredygtig håndtering, hvor materialerne får et efterliv i en rekreativ park. Ydermere er det et vellykket og lokalt eksempel på, at det giver mening at tænke den grønne omstilling ind i byggeriet.

Det har altid været sund fornuft at forsøge at undgå at affaldet – eller ressourcerne – fra de nedrevne ejendomme ender i deponi. Det vil som minimum sige omdannelse til energi på forbrændingen. Entreprenørerne arbejder derfor hårdt på at få restressourcerne endnu højere op i affaldshierarkiet (forebyggelse, genbrug og genanvendelse). Igennem et samarbejde bliver det muligt at få flere affaldsressourcer højere op i hierarkiet alene af den årsag, at man nu kan indsamle store mængder af flere fraktioner, så det bliver interessant for en aftager at købe det.

Se TV2 MidtVests reportage om symbiosen- ’Konkurrenter i grønt samarbejde’ her.

Better World Fashion en aalborgensisk virksomhed, som har fokus på bæredygtig mode fx læderjakker, tasker og andet tilbehør. Hos Better World Fashion handler det om bæredygtighed og genbrug, men lige så meget om, at slutresultatet skal være fantastisk. Better World Fashion mener, at forurening og negativ miljøpåvirkning af forbrug grundlæggende opstår, fordi producenterne og virksomhederne ikke har været i stand til at kunne producere et produkt, som ikke har nogen form negativ miljøpåvirkning.

Better World Fashions læderjakker både til kvinder og mænd er fx lavet af 98 % genbrugt læder og er 100 % unikke. Læderjakkerne er netop unikke, fordi Better World Fashion bruger genbrugsmateriale og derfor kommer læderjakkerne ikke til at ligne hinanden.

Better World Fashion har samarbejdet med Aalborg Universitet, om at lave en LCA-analyse af læderjakken og ved derfor præcis, hvor bæredygtig den er. En læderjakke fra Better Word Fashion kan, sammenlignet med en ny læderjakke af jomfruelige materialer, sparer 340 liter vand, 16 kg CO2, 6 kg affald og 3,75 kg kemikalier. Derfor har hver solgt jakke fra Better World Fashion en positiv miljøpåvirkning. Målt ud fra det samlede salg, har Better World Fashion sparet verden for over 100.000 liter vand, 4,8 tons CO2, 1,8 ton affald og 1 ton kemikalier.

Vi er med i symbiosen sammen med Pakkeriet i Hadsund som potentiel aftager af den flamingo (EPS), som Pakkeriet måtte indsamle og komprimere. Samarbejdet omfatter også levering af viden samt tilbud på komprimatorer.

Det indsamlede EPS forarbejder vi på vores extrudere og indsætter det i kredsløbet som nyt recyclet EPS fx i vores nye 100% recyclede isoleringsmateriale GREENLINE. For hvert kilo EPS, produceret i vores 100% recycled materiale, sparer vi 5,6 kg. CO2 i forhold til ny EPS.

Per Faber, Sourcing Manager, BEWI Circular Denmark A/SI BEWI har vi sat ambitiøse mål for vores arbejde med bæredygtighed. Strategien dækker hele vores værdikæde og rækker helt frem til 2030. I praksis handler det om at blive cirkulære baseret på vedvarende energi, at deltage aktivt i partnerskaber for fx at reducere transporten/CO2 udledning og at bidrage til et inkluderende samfund med en positiv social påvirkning for alle på tværs af vores værdikæde.

Bobach Stålentreprise has been strongly involved in symbiosis development in Aalborg. For example, the company is part of a symbiosis, in which a handful of production companies share residual materials with the socio-economic Råt&Godt, transforming residual products into modern, long-lasting design furniture. Environmental and economic gains go hand in hand in this symbiosis: Bobach Stålentreprise saves money, as they do not have to pay for the disposal of the waste themselves, Råt&Godt gains a financial benefit from the sale of the furniture, and the collaboration provides numerous environmental and social benefits in the community. At the same time, the symbiosis has been a positive media story and provided a platform for new collaborations between the companies.

Bobach Stålentreprise is also in symbiosis with a number of steel fabrication companies in Aalborg East, which receive corrugated plastic sheets in the form of spacers between the steel plates. Although the 2-10 mm thick plastic sheets are made of a pure plastic material and are therefore very suitable for recycling, the individual company’s quantities have been too small to bear the logistical costs of recycling. Therefore, the plastic sheets have typically thus far been sent for incineration along with other waste fractions. In the symbiosis, they must now be collected at Aalborg Recycling with a view to becoming new plastic of similarly high quality.

It is a collaboration we are proud of!

Helle Bobach, DirectorBobach Stålenterprise A/S is a certified fabrication and engineering company, which executes everything from small tasks to large advanced steel structures. The company designs and projects tasks within balconies, railings, stairs and others. It is a multigenerational family-owned business that takes a practical approach to sustainability. Obviously, it makes sense to save on resources!

Bålhyttesymbiosen er et samarbejder mellem de fire entreprenører, Thisted Kommune og Borgerforeningen i Villerslev. Her arbejdes der benhårdt på at indsamle de gode restmaterialer mursten og træ, der findes i nedbrydningen af huse. Når Bålhytten i Villerslev står færdig, vil det være et klokkeklart eksempel på en bæredygtig håndtering, hvor materialerne får et efterliv i en rekreativ park. Ydermere vil det statuere et lokalt eksempel på at det giver mening at tænke den grønne omstilling ind i byggeriet.

Se TV2 MidtVests reportage om symbiosen- ’Konkurrenter i grønt samarbejde’, her.

Bøgelund Maskinstation er én ud af fire lokale og mindre entreprenørvirksomheder, der står for hovedparten af nedrivning af saneringsmodne ejendomme i Thisted Kommune. I samarbejdet om udsorteringssymbiosen mellem de fire entreprenører; Allan Thomsen, Koldby entreprenøren, Aarup kloak og Bøgelund Maskinstation kommer det til udtryk hver for sig kan entreprenørerne ikke skabe kritisk masse i affaldsfraktionerne såsom mursten, beton, træ og tegl, så de kan afsættes til attraktive markedspriser og samtidig være bæredygtige. En stor del af materialerne er derfor før symbiosen anvendt til forbrænding eller deponi. Derfor har GRØNS deltagelse i symbiosen f.eks. handlet om at skaffe fælles viden om markedet for affald og om at finde fælles fodslag. Helt konkret arbejder vi på at finde en fysisk lokalitet, hvor vi kan samle affaldsressourcerne inden videresalg. På denne måde sikres det at ressourcerne håndteres på bæredygtig vis både økonomisk, miljømæssigt og socialt forsvarligt.

Saneringsmodne huse genopstår som bålhytte

Udover symbiosen med udsorteringspladsen samarbejder de fire entreprenører også med Borgerforeningen i Villerslev. Her arbejder de benhårdt på at indsamle gode restmaterialer i form af mursten og træ fra nedrivningshuse til opførsel af byens nye bålhytte. Når hytten i Villerslev står færdig, vil det være et klokkeklart eksempel på en bæredygtig håndtering, hvor materialerne får et efterliv i en rekreativ park. Ydermere er det et vellykket og lokalt eksempel på, at det giver mening at tænke den grønne omstilling ind i byggeriet.

Vi gør det for at bidrage til en bedre verden for vores børn og børnebørn, men vi gør det også fordi, det er en god forretning

Kurt Immersen, Indehaver, Bøgelund MaskinstationDet har altid været sund fornuft at forsøge at undgå at affaldet – eller ressourcerne – fra de nedrevne ejendomme ender i deponi. Det vil som minimum sige omdannelse til energi på forbrændingen. Entreprenørerne arbejder derfor hårdt på at få restressourcerne endnu højere op i affaldshierarkiet (forebyggelse, genbrug og genanvendelse). Igennem et samarbejde bliver det muligt at få flere affaldsressourcer højere op i hierarkiet alene af den årsag, at man nu kan indsamle store mængder af flere fraktioner, så det bliver interessant for en aftager at købe det.

Se TV2 MidtVests reportage om symbiosen- ’Konkurrenter i grønt samarbejde’, her.

Læs mere om symbiosen her.

Foto: Erhvervsstyrelsen

Brunø Stål is active in a number of symbioses with companies in the local area. The company collects a sizable quantity of corrugated plastic sheets used as spacers between the steel sheets delivered from their supplier. This generates an amount of waste that can be readily recycled, as the material is clean. Together with other smaller steel processing companies in the Aalborg area, Brunø Stål will collect the plastic sheets and jointly ensure that they are transported for recycling, rather than incineration.

In addition, an energy consultant investigated how the buildings could be heated and energy improved. Although the investigation did not yield a basis for a symbiosis on that issue, Brunø gained specific knowledge of the decision-making process, which also yielded an environmental effect.

It is good to have a common collection system, so we can take care of the environment.

Torben Kjær, Director and ownerBrunø Stål ApS is a steel fabrication company in Aalborg, which specialises in the fabrication of steel and leaf springs as well as project engineering tasks in steel. The company manufactures and assembles i.a. columns, beams and stairs in steel as well as railings and guards. Brunø Stål is actively working to improve their own buildings in order to save energy for heating and ensure well-being and an optimal working environment. The company also places great emphasis on resource consumption both in terms of transport, material consumption as well as maintenance and repair of equipment and machinery. One repairs because it makes sense and takes care of the equipment. It is all part of doing a good job.

The asphalt producer Colas Danmark A/S has joined forces in a symbiosis with Nordjyllands Power Station for the exchange of the residual by-product fly ash. Fly ash comprises fine particles, a by-product of incineration at the power station. Instead of sending this by-product to the landfill, it is used i.a. at Colas Denmark in the production of asphalt. Apart from Colas Danmark, the local cement producer Aalborg Portland also receives some of the fly ash.

As a global market leader, the Colas Group is conscious of its responsibility for the climate. Consequently, the group has over the years introduced a large number of global development initiatives. We will further bolster this work in the coming years i.a. with a strategy for CO2 emissions and biodiversity.

Peder Friis Erlandsen, QHSE and CSR Manager for Colas Danmark A/SColas is a nationwide asphalt contractor with asphalt factories, gravel pits and departments spread across the country. Colas is strongly focused on the environment and develops and markets increasingly sustainable products and innovative solutions for infrastructure. Colas’ objective within sustainability is to contribute to a more responsible value chain by i.a. substituting virgin materials for recycled ones whenever possible and reducing the company’s CO2 emissions. The company has a long-term objective of sustainable development with economic growth, while respecting people and biodiversity. Colas’ environmental management system is certified to the DS/EN ISO 14001 standard, and Colas plays an active role in the Danish and international environmental work of the asphalt industry.

There are a number of companies in Aalborg East that contribute to various symbioses.

One symbiosis involving companies in Aalborg East is product-to-service offers, in which KS Group participates. Customers can either choose to buy or lease such equipment as handcarts from the company. This symbiosis demonstrates how new business collaborations with other companies involving leasing can lead to optimisation of resource and material consumption.

Various companies in Aalborg East, especially housing associations, are also collaborating with De Grønne Hvidevarer (DGH), which has been collecting and renovating domestic appliances for resale to private individuals for several years. In this symbiosis, new models are tested for sale to companies based in Aalborg East. The aim is to make it easy to replace domestic appliances with renovated ones delivered with a warranty and possible service agreement. The extended lifetime of the appliances yields a significant environmental effect by reducing the need to produce new appliances.

This broad group of symbiotic companies also includes Kingo Recycling’s customers. For a number of years, they have been sending oil contaminated process and wastewater to South Jutland for treatment. Consequently, several hundred heavily laden trucks had to drive through Jutland each year. Kingo Recycling has now built a business based on local water treatment that minimises the need to transport it out of North Jutland. This symbiosis is a good example of how a resource can be turned into a business opportunity by retaining it in the immediate area while enabling new symbioses between companies.

Grocery stores in the area deliver their surplus heating to the district heating network, thereby contributing to greener district heating.

Aalborg Crematorium collaborates with Aalborg Utilities as a part of the heat symbiosis in Aalborg, whereby surplus heat is supplied from the crematorium to the district heating network. Surplus heat from the companies plays a major role in the development of Aalborg’s green heat supply, where conventional heat sources are substituted by more sustainable ones.

Dansk Boligstål A/S manufactures stainless steel fixtures and fittings, steel and aluminium constructions, ship fittings and Corian®. The company annually produces more than 5,000 countertops in Corian®. Corian® is a composite material. Once mixed, the components of the material cannot be separated again, making recycling very difficult. In collaboration with the Sustainable Synergies project, Dansk Boligstål has been engaged in a consulting process to develop collaborations for the recycling or reuse of Corian offcuts, a by-product of their production. The company is now in full swing to realise this symbiosis.

Our clear green profile has already proven to be important for our customers. Social responsibility, proper conditions, waste and residuals minimised and treated properly.

Michael Tsatiris, CEODansk Boligstål has a large number of sustainability initiatives in place. They support Danish Hospital Clowns through the collection of recycling deposits. All material residuals are sorted and the different residual fractions are recycled. The company is a certified Corian® distributor and supplies the fine, uniform table tops for constructions and renovations. Material residuals and offcuts cannot be recycled and there is no environmentally friendly solution for its disposal. The company took up this challenge through its collaboration with Sustainable Synergies. Innovation and readiness for change ensure the constant expansion and development of the company’s green agenda.

Sammen med Simested Vognmandsforretning sørger vi for, at landbrugsplast genanvendes lokalt. Vognmandsforretningen har tidligere kørt plasten til Tyskland for at få den regranuleret – nu kører de det til os i stedet. Det sparer lidt mere end 600 km transport pr. læs til gavn for miljøet.

Dansk Regranulat ApS er en plastgenanvendelsesvirksomhed, der er med til at flytte Danmark fra at være en afbrændingsnation til at være et land, hvor genanvendelse kommer først.

Plast er en værdifuld ressource med mange unikke egenskaber, og kan bl.a. genanvendes til at designe løsninger på samfundets udfordringer. Det kræver, at mange forskellige aktører i samfundet, herunder plastbranchen selv, forandrer sig, hvis vi skal komme i mål med en cirkulær økonomi indenfor plastområdet. Her vil Dansk Regranulat ApS være med til at vise vejen.

Dansk Regranulat ApS tager ansvar og er med til at reducere CO2-udledning og miljøbelastning ved at genanvende landbrug- og industriplast, som er PE folieplast, så det bruges til ny plastproduktion i stedet for forbrænding.

Mange danske havne får olievand som affaldsprodukt fra skibene, der anløber havnene. Hvordan man omdanner olievandet til et produkt, som kan recirkuleres, undersøges i denne symbiose.

De Grønne Hvidevarer (DGH) has been collecting and renovating domestic appliances for resale to private individuals for several years. In this symbiosis, new models are tested for sale to companies based in Aalborg East. The aim is to make it easier for companies and housing associations to replace worn-out domestic appliances with renovated ones delivered with a warranty and possible service agreement. The extended lifetime of the appliances yields a significant environmental effect by reducing the need to produce new appliances.

There are so many good appliances that are discarded, because it does not pay to have them repaired!

Tommy Martin Blaabjerg, owner and founderDe Grønne Hvidevarer works with sustainable recycling by collecting, repairing and reselling domestic appliances that have been discarded. The domestic appliances are sorted directly from the Danish streams of electrical and electronic waste, after which they are repaired, prepared and resold. Rather than being discarded and ending up in a remelting process, the appliances are recycled, creating less waste, less CO2 emissions, less waste of resources, and significantly reduced environmental impact.

Farms near Nordjyllands Power Station has previously pumped surplus water from the fields into the Limfjord. Now the farms participate in a symbiosis, whereby approx. 120,000 m3 of water is collected and piped to Nordjyllands Power Station. There it is used in a process that produces gypsum. Consequently, the surplus water replaces groundwater in the process.

Udsorteringspladsen opstod igennem partnernes arbejde i symbioseprojektet GRØN mellem de fire entreprenører; Allan Thomsen, Koldby entreprenøren, Aarup Kloak og Bøgelund Maskinstation. Den skal være den fysiske lokalitet, hvor entreprenørerne kan samle kritisk masse af affaldsressourcerne inden videresalg. På denne måde sikres det, at ressourcerne håndteres på bæredygtig vis både økonomisk, miljømæssigt og socialt forsvarligt.

Materialerne der håndteres, kan se ud som følgende:

Det har altid været sund fornuft at forsøge at undgå at affaldet – eller ressourcerne – fra de nedrevne ejendomme ender i deponi. Det vil som minimum sige omdannelse til energi på forbrændingen. Vi arbejder dog hårdt på at få restressourcerne endnu højere op i affaldshierarkiet (forebyggelse, genbrug og genanvendelse). Igennem et samarbejde med vores kolleger vil det blive muligt for os at få flere affaldsressourcer højere op i hierarkiet alene af den årsag, at vi nu kan indsamle store mængder af flere fraktioner, så det bliver interessant for en aftager at købe det af os. Vi gør det for at bidrage til en bedre verden for vores børn og børnebørn, men vi gør det også fordi, det er en god forretning.

Se TV2 MidtVests reportage om symbiosen- ’Konkurrenter i grønt samarbejde’, her.

The company has been involved in the development of a number of symbioses in recent years. The company uses e.g. in its machines a so-called sieve belt, a conveyor belt of 4.5 x 75 meters made of very strong polyester. It is changed ten times a year and it would be a great advantage to be able to reuse it afterwards. Consequently, Fibertex together with other companies teamed up with the socio-economic workshop Råt&Godt and an industrial designer to develop a new design line that utilises the surplus materials of the companies. Initially, a series of tables and lamps are being developed by the designer Mikkel Huse. The combination of strong design and local production in Aalborg East are key elements in the collaboration.

Moreover, the concentrated nature of the business park in the Aalborg East area also affords opportunities for a common recycling scheme for wooden pallets, of which Fibertex is a part. At many companies today, it is customary to discard used pallets, and companies often pay for collection and disposal. Consequently, there is a potential for increased recycling of wooden pallets, which makes good sense both economically and environmentally. Therefore, Fibertex Personal Care is also linked to a recycling scheme for the recirculation of pallets among companies, with the Hobro-based company LC Emballage as the key logistics hub and distributor.

We would never have thought of making designer lamps from our sieve belts.

Mette Due, Quality and Environmental Manager, Fibertex Personal CareFibertex Personal Care produces non-woven materials for the hygiene industry. The company’s product portfolio illustrates their importance as a player in the hygiene industry’s value chain. Depending on the technology platform applied, non-woven fabrics have specific properties that are used in a wide range of areas. Specific properties include absorption, liquid repellence, elongation, softness and strength, etc. Colours, fragrances and other features can be added to the non-woven fabrics in a special printing process.

Their motto “sustainable is possible” defines the company’s ambition and desire to create sustainable solutions and constantly push the boundaries to make their production more sustainable. Of the UN’s 17 Sustainable Development Goals, Fibertex Personal Care is committed to observing six of them in particular, aimed at supporting sustainability and global development.

En konkret symbiose mellem en fiskeopdrætsvirksomhed og Maripure Seaweed ApS undersøges. Nordsøen Forskerpark er også involveret, fordi der udvikles et helt nyt produkt og helt nye produktionsprocesser.

Vandet, der ledes væk fra fiskeopdrættet, er næringsrigt, og virksomhederne undersøger, om exitvandet kan bruges i Maripures produktionen af en algeart, der kan forarbejdes til foder til økologisk kvæg. Indtil videre udveksles der viden, og Maripure arbejder på at etablere et produktionsanlæg i forskerparken fra andet halvår 2023.

Vi indgår i symbiosen med Strandby Fiskerihavn sammen med en kollega i vodbinderbranchen og to vodbinder-firmaer. Vi kommer med viden om, hvordan et trawl i praksis håndteres lige fra bestilling og brug til bortskaffelse. Vi ser også en fordel i at deltage i symbiosen, fordi vi får ny viden. Snart skal vodbinderne, som laver trawlene, nemlig stå til ansvar for, hvad der sker med dem, når de bliver kasseret.

Som fiskere støder vi tit på affald, der flyder rundt i havet. Vi er derfor opmærksomme på at bringe vores eget affald med tilbage til havnen, som jo også har aftagerpligt.

Aalborg East Business Park is home to numerous companies that generate oily process and wastewater in their operations. These companies have thus far transported this water to South Jutland for treatment, oil separation and cleaning of its components. The unnecessary transport of tonnes of water on heavily laden tanker trucks formed the basis for a collaboration between Kingo Recycling and the companies in Aalborg East. The contaminated water is collected and treated locally in Aalborg and separated from the oil. Fortum still receives the environmentally hazardous components of the mixture, which they are experts at processing properly. The symbiosis not only represents an environmental benefit due to the CO2 savings by minimising transport, but also exemplifies a business opportunity arising on the basis of a resource that negatively impacts the environment and which can be treated more efficiently for both customers, companies and the environment.

Treatment and separation are continuously improved, with the aim of increasing the quality sufficiently, so that the recycled oil can substitute new oil products.

Fortum Waste Solutions A/S is a part of the Nordic business unit “Recycling & Waste” in the energy group Fortum. The business unit has a total of 750 employees working in Finland, Sweden, Denmark and Norway.

The aim of the company is to conserve natural resources through sustainable solutions for the detoxification, recycling, recovery and final treatment of hazardous waste. Consequently, enabling the recycling of valuable materials and the promotion of circular economy. The customer-specific solutions optimise resource and cost efficiency.

Fortum’s mission is to engage with customers and communities to drive the transition towards a cleaner world. This transition is accelerated by transforming the energy system, improving resource efficiency and delivering innovative solutions. Offering customers and society sustainable solutions based on clean energy ensures a fast and reliable transition to a carbon-neutral economy. The company aims to be completely carbon-neutral by 2050.

Vi indgår i symbiosen med Strandby Fiskerihavn sammen med en kollega i vodbinderbranchen og to fiskere. Vi ved, hvor meget og hvor mange forskellige typer plast, metal og andet materiale, der medgår til produktion af et fisketrawl.

Vi forsøger altid at genbruge mest muligt af det gamle, kasserede trawl, når vi samler et nyt. Det er typisk floats og kæder, der kan bruges igen. Det vil sige, at vi ved produktion og reparation af et nyt trawl forsøger at indtænke, at delene en gang skal kunne genbruges. Herudover handler det om at kunne levere den kvalitet, som vores kunder efterspørger, så kvalitet i form af holdbarhed er væsentligt for os.

Over the years, numerous companies in the industrial area of Aalborg East have been sending process water and wastewater containing oil for treatment to South Jutland. Consequently, several hundred heavily laden trucks have to drive through Jutland every year. Kingo Recycling has built a business based on local water management, so that as little as possible has to be transported away from North Jutland. Kingo Recycling delivers the oil-water mixture to Avista, which separates waste products and water from the oil, so that it can then be recycled. The waste materials are managed at Fortum. In collaboration with Sustainable Synergies, a number of symbiosis opportunities with local companies have been considered as a part of business development.

The symbiosis is a good example of how a resource can be turned into a business opportunity by retaining it in the immediate area, while generating opportunities for new symbioses between companies. Consequently, it has also been investigated, whether the separation can be of such a high quality that the oil can replace the consumption of new oil products at other companies.

Through the massive saving in transport, the symbiosis yields clear environmental benefits that include a significant reduction in CO2 emissions.

Kingo Karlsen A/S is a demolition company that works determinedly to develop sustainable solutions and disseminate knowledge and expertise within the sustainable demolition and recycling of building materials. The company is committed to six of the UN’s 17 Sustainable Development Goals in particular, and their vision is to become the Nordic region’s synonym for environmentally sound demolition conducted with respect for people and the world we live in.

Kingo strives to ensure that environmentally hazardous substances do not spread to the environment, groundwater and the world’s oceans by sorting hazardous substances from the building mass during processing. Once hazardous substances have been removed and delivered to an approved waste recipient, the remaining clean building mass can be reused and recycled for the benefit of the environment. Kingo is also keenly focused on sustainable industrialization by e.g. treating and reprocessing construction waste products for recovery. The quality of the end product is so pure that the soil can be used for special purposes demanding extraordinary requirements for quality.

The company recycles up to 98% of the building materials processed, and the goal is for recycled and reused building materials to become the preferred material choice in new construction projects.

A small company with a potentially huge environmental effect. Kirk Skumteknik develops, produces and installs insulation solutions for district heating wells. Residuals from their production could be incorporated as insulation material into the products of RC Beton, which produces concrete elements with built-in insulation. Moreover, the company received assistance to expand its business area, as spreading the solution will beneficially impact the environment. Today, the high-tech district heating pipes are connected in uninsulated holes (wells) in paths and roadsides, from which heat is lost.

It is a completely new product - a solution you cannot do without.

Jesper Sand Kirk, business ownerKirk Skumteknik offers a complete insulation solution for district heating wells. The insulation enables a significant reduction in heat loss from the district heating network, which in itself is economically viable, but also minimises and eliminates operational and maintenance challenges.

Koldby Entreprenør A/S er én ud af fire lokale og mindre entreprenørvirksomheder, der står for hovedparten af nedrivning af saneringsmodne ejendomme i Thisted Kommune. I samarbejdet om udsorteringssymbiosen mellem de fire entreprenører; Allan Thomsen, Koldby Entreprenør, Aarup Kloak og Bøgelund Maskinstation kommer det til udtryk, at hver for sig kan entreprenørerne ikke samle nok af hver type affald, såsom mursten, beton, træ og tegl, så de kan afsættes til attraktive markedspriser og samtidig være bæredygtige. En stor del af materialerne er derfor indtil nu blevet forbrændt eller deponeret. Derfor har virksomhedernes deltagelse i symbiosen f.eks. handlet om at skaffe fælles viden om markedet for affald og om at finde fælles fodslag. Helt konkret arbejder vi på at finde en fysisk lokalitet, hvor vi kan samle affaldsressourcerne inden videresalg. På denne måde sikres det, at ressourcerne håndteres på bæredygtig vis – både økonomisk, miljømæssigt og socialt forsvarligt.

Saneringsmodne huse genopstår som bålhytte

Udover symbiosen med udsorteringspladsen samarbejder de fire entreprenører også med Borgerforeningen i Villerslev. Her arbejder de benhårdt på at indsamle gode restmaterialer i form af mursten og træ fra nedrivningshuse til opførsel af byens nye bålhytte. Når hytten i Villerslev står færdig, vil det være et klokkeklart eksempel på en bæredygtig håndtering, hvor materialerne får et efterliv i en park til fælles glæde for borgerne. Ydermere er det et vellykket og lokalt eksempel på, at det giver mening at tænke den grønne omstilling ind i byggeriet.

Det har altid været sund fornuft at forsøge at undgå at affaldet – eller ressourcerne – fra de nedrevne ejendomme ender i deponi. Det vil som minimum sige omdannelse til energi på forbrændingen. Entreprenørerne arbejder derfor hårdt på at få restressourcerne endnu højere op i affaldshierarkiet (forebyggelse, genbrug og genanvendelse). Igennem et samarbejde bliver det muligt at få flere affaldsressourcer højere op i hierarkiet alene af den årsag, at man nu kan indsamle store mængder af flere fraktioner, så det bliver interessant for en aftager at købe det.

Se TV2 MidtVests reportage om symbiosen- ’Konkurrenter i grønt samarbejde’, her.

Vi ønsker at omlægge vandforbruget til vaskeprocesserne, så der ikke længere bruges rent drikkevand, men fremover bruges renset spildevand suppleret med opsamlet regnvand fra tagflader på fabrikken. I samarbejde med Mariagerfjord Vand i projekt GRØN undersøgte vi mulighederne for omlægning. Rensning af spildevand er vi nået i mål med, mens opsamling af regnvand til brug i stedet for frisk vand kræver myndighedsgodkendelse og yderligere undersøgelser.

Kruse Vask sikrer, at deres kunder er i centrum i alle virksomhedens processer, derfor anvendes kun produkter og vaskemidler, som er miljøgodkendt og Svanemærkede, så de overholder skrappe miljøkrav og tage hensyn til den menneskelige sundhed.

Der arbejdes hele tiden på at reducere energi- vand- og kemikalieforbrug for at sikre, at virksomheden kan levere miljørigtige tekstilløsninger. Kruse Vask ønsker at tage globalt og lokalt ansvar. Derfor samarbejder vi kun med leverandører, der sikrer et godt arbejdsmiljø og ikke benytter sig af børnearbejde i tekstilproduktionen. Vores eget arbejdsmiljø lokalt har modtaget Arbejdstilsynets grønne smiley.

Cirkularitet tænkes ind i produkter og services, ressourceforbruget minimeres og social ansvarlighed vægtes højt. Materialer fra Kruse Vask genanvendes gennem samarbejde med socialøkonomiske virksomheder lokalt, som skaber jobs og et mere rummeligt arbejdsmarked, og produkter, der kan genbruges, doneres til herberger og krisecentre.

Branchens mindste forbrug af vand og kemi og elforbruget kommer fra egne solceller og fra el-leverandøren fra vind, sol og naturgas. Sidstnævnte arbejder vi på at udfase.

FN’s Verdensmål, særligt 3, 8, 9, 12 og 17 er integreret i det daglige arbejde.

The transition from selling products to selling services is often mentioned as a good way to reduce environmental impacts, because it can lead to less ‘equipment’ laying around at the customers. In this symbiosis, the KS Group demonstrates how this can be specifically done based on their sales of transport equipment. In their new business model, customers can either choose to buy or lease e.g. handcarts from the company. The service model yields clear positive environmental and energy effects and affords KS Group a new business area, where they hold a strong position in high-quality transport products. At the same time, the symbiosis illustrates how new business collaborations with other companies within leasing can lead to optimal resource and material consumption.

This benefits both business and the environment.

Claus Svensk Jessen, CEOKS Group operates within four key areas: wheels, transport equipment, ergonomics and fixtures, providing a 360-degree solution that addresses all the customers’ needs from project development to workstations.

Private individuals often use moving boxes over and over again, but other cardboard boxes are generally not recycled. Consequently, there is tremendous potential for making cardboard box consumption more circular, with LC Emballage as a focal point in the symbiosis to realise this potential in Aalborg. The company in Hobro is collaborating with companies in Aalborg East to achieve a cheaper and more environmentally friendly packaging solution. LC Emballage offers to buy used cardboard boxes from one company and sell them to another, providing benefits for all parties. LC Emballage buys used cardboard boxes at a significantly better price from the individual company than if the boxes had ended up as recycled or combustible waste.

LC Emballage also engages in a symbiosis for the recycling of wooden pallets. The company purchases a wide variety of pallets and pallet frames, including disposable pallets and damaged pallets, which are repaired, sorted and resold from their warehouse in Hobro. Through such a scheme, companies in 9220 area can have their pallets collected and receive a modest sum for those pallets that can be recycled. It is a simple, stable, and environmentally friendly solution to tackle the issue of unreturnable pallets.

When companies in an area work together to recycle pallets and cardboard, logistics become better and recycling more attractive.

Erik Lund, business ownerLC Emballage’s business model is recycling. The environmental effect is central to the company’s daily operations and creates the possibility for a consistent supply of pallets for multiple purposes. Extensive experience ensures that there are buyers for each pallet stored in their large warehouse in Hobro. Cardboard boxes is a newer business area and the business is growing right now. It started with recycling and repairing pallets, later it turned out there are also tremendous environmental benefits and business opportunities in cardboard boxes. Subsuppliers are especially interested in recycling boxes that are in perfect condition. The boxes are used everywhere where it is not important to have your own logo on the packaging, or where customer company wants to signal their consideration for sustainability.

The company was the initiator of a symbiosis in Aalborg. One partner is Salling Entreprenørfirma, which collects large quantities of wood materials from the demolition of old buildings. Another partner has large quantities of functional steel bolts that have only been used once in packaging. Instead of discarding these residual materials, both steel bolts and wood were used in the manufacturing of furniture. The symbiosis was based upon demand for sustainable products.

The company’s core business is custom furniture. When customers order a high-quality product that is really desired, it is less likely to be replaced. Tailored durable solutions are sustainable as opposed to use-and-throw-away ones, because they ensure that production directly matches the individual specifications of each order. Thereby minimising waste. Timeless and stylish quality solutions afford a longer product lifespan, which is important for sustainability.

To refresh sold furniture items, the company offers customers the possibility to order sanding and new oiling of items, or even new legs, for a modest price. A new look almost for free – that extends its lifetime. Both Azobé wood from wharfs and ship planks of other types of wood with patina are used in the production and design of new furniture. This is advantageous both from a design and environmental perspective.

There are also specific projects in the pipeline to develop a range of outdoor furniture made from a residual material – a granulate of clothing fibres. A new tabletop concept is also under development, using offcuts from production that are cut into rods and assembled to form a strong, durable tabletop, which is then veneered with oak. This reduces waste and generates a new quality product.

En konkret symbiose mellem en fiskeopdrætsvirksomhed og Maripure Seaweed ApS undersøges. Nordsøen Forskerpark er involveret, og tilbyder tilknyttede produktionsarealer og bindeled imellem de to virksomheder. Samtidigt er der en faglig vidensdeling imellem alle parter, da der skal bygges nye systemer og genanvendelse af en ubrugt ressource, som ikke før er blevet undersøgt som værdifuld. Procesvandet, som ledes væk fra fiskeopdrættet, er næringsrigt, og virksomhederne undersøger, om procesvandet kan bruges i Maripures kultivering af alger, der kan forarbejdes til drivhusgasreducerende fodermaterialer til både konventionelt og økologisk landbrug. Indtil videre udveksles der viden, og Maripure arbejder på at etablere et produktionsanlæg i forskerparken fra andet halvår 2023.

Grundlaget for virksomhedens aktiviteter er at udvikle og introducere en vedvarende, biologisk foderkilde, der vil reducere CO2e-udledningen fra animalsk landbrug med kvæg. Kultiveringen og efterbehandlingen af råmaterialet er en ny kilde til forurening, som skal balanceres med gevinsten af produktet. Samarbejdet med Port of Aalborg omhandler genanvendelsen af en rest-ressource for at reducere produktionsomkostningen. Bæredygtighed er derfor kernen, men også det gennemgående fokus for udviklingen, i vores aktiviteter.

Maskinfabrikken Fuglsangs Eftf. produces steel components, i.a. for wind and offshore projects. As part of the Sustainable Synergies project, the company has been investigating the possibilities of recycling plastic sheets from the packaging of raw materials by participating in a symbiosis with Aalborg Recycling.

Maskinfabrikken Fuglsangs Eftf. moved to Port of Aalborg in 2019 in connection with a major expansion and modernisation of its production facilities. This afforded improved conditions, especially for operations within their offshore and wind energy department. The company currently has around 100 employees, divided between CNC machining, water, plasma and laser cutting of components, the manufacturing of structures for the offshore and wind energy sector, as well as assembly and service.

The move to a centralised business park location offers advantages. It is the first step in becoming a greener company. Compared to the previous facilities, the new factory affords savings in both heat and energy resources. There is less transport internally, improved waste sorting and more recycling. The infrastructure also provides greener transport of large-scale structures, both by sea and freight transport by rail. This yields positive environmental impacts. Collaboration and development opportunities are also enhanced, because customers are closer, laying the foundation for potential new symbioses in the future.

NB Ventilation is involved in a number of symbiotic collaborations due to the large amount of Aluzinc offcuts that occur in their production of ventilation systems. A neighbouring company, Aalborg Profil- og Smedeværksted, is interested in using some of the material. In addition, NB Ventilation and companies from other industries are part of a joint symbiosis, in which they supply surplus materials to the socio-economic workshop Råt&Godt. Here, a new design line based on surplus materials is being developed by an industrial designer, especially for production at Råt&Godt. Initially, a series of tables and lamps are being developed by the designer Mikkel Huse. The combination of strong design, good residual materials and versatile local production in Aalborg East are the key elements in the collaboration.

NB Ventilation also engages in symbiosis with a number of steel processing companies in Aalborg East, which receive corrugated plastic sheets that act as spacers between the steel plates from their supplier. Although, the 2-10 mm thick plastic sheets are made of a pure plastic material and therefore easily recyclable, the individual company’s quantities have so far been too small to justify the logistical cost of recycling. Consequently, the plastic sheets have typically been sent for incineration along with other waste fractions. In the symbiosis, the sheets are collected with a view to becoming new plastic of a correspondingly high quality.

Hand tools that no longer work are typically discarded as repair is expensive. This is not the case at NB Ventilation. The company has joined forces with the socio-economic company Råt&Godt to prove that it is possible to extend the life of a large proportion of the hand tools that are discarded. At best, the company takes back the repaired hand tool for the benefit of both the economy and the environment.

Our core business is green - now the company must be too!

Per Højbjerre, CEONB Ventilation A/S produces ventilation units for both housing, office and industry, primarily focused on comfort ventilation, industrial ventilation and energy-efficient heat recovery. Production ranges from small residential units, units with built-in fire compartment, ordinary comfort systems, to huge customised industrial systems with airflow of more than 120,000 m3/h. All in all, the product, ventilation with heat recovery, is centred around optimal utilisation of resources. The company is developing from a craft-based production to a modern industrial manufacturer through development projects with a particular emphasis on sustainable transition.

The company collaborates with KS Gruppen to offer leasing solutions rather than sales of products. This yields positive environmental effects.

Hos Nordværk producerer vi miljørigtig fjernvarme og elektricitet af energien i det affald, som vi modtager fra borgere og virksomheder. Vi leverer overskudsvarmen fra vores energianlæg til Aalborg Forsyning, der sender den videre ud i byens fjernvarmenet. Sammen med Nordjyllandsværket leverer vi mere end halvdelen af varmebehovet i Aalborg Kommune.

Sammen med selskabets ejere har vi i mange år tilstræbt at få det genanvendelige affald ud af det forbrændingsegnede affald. Denne indsats bliver nu yderligere forstærket med aftalen om klimaplanen på affaldsområdet. Vi forventer fortsat at kunne levere en væsentlig del af varmebehovet til Aalborg Forsynings fjernvarmenet, idet den ledige kapacitet, der kan opstå ved udsortering af genanvendeligt affald, kan bruges til energiproduktion med grønne brændsler fx haveaffald – eller affald fra andre områder i Danmark, hvor udtjente forbrændingsovne bliver lukket ned.

Hver dag sikrer vi en miljørigtig håndtering og bortskaffelse af det affald, vi modtager fra de nordjyske kommuner, virksomheder og private. Affaldsforbrændingen sker i et moderne energianlæg med effektiv røgrensning, der både skåner miljøet og skaber varme til Aalborg Forsynings fjernvarmekunder.

Frem til 2025 bliver området omkring Nordværk udbygget i forbindelse med etableringen af Nordjyllands Ressourcepark. Etableringen sker i samarbejde med Aalborg Forsyning og omfatter bl.a. en ny, moderne genbrugsplads til byens borgere og en ressourcehal til håndtering og oplagring af de mange affaldstyper, vi afsætter til genanvendelse. I denne forbindelse afdækker vi desuden behovet for en eventuel tilpasning vores eksisterende affaldsenergianlæg, så det matcher fremtidens behov.

Nørager Mejeri har samarbejdet med AN Energi om at levere overskudsvarme fra produktionen af ost til det lokale fjernvarmenet. Det vil resultere i en reduktion i brugen af biobrændsel tilsvarende mængden af overskudsvarme.

Hos Nørager Mejeri arbejdes der på at sikre den laveste CO22 påvirkning pr. kg ost, der produceres. Dette arbejde sker gennem mange initiativer, blandt andet gennem at påvirke transporten af produkter, valg af emballage og gennem et tæt samarbejde med med Nordex Foods’ mælkeleverandører om dyrevelfærd.

CSR er prioriteret højt og er derfor med til at guide beslutningsprocesser, så det sikres at vi giver værdi både for mennesker, miljø og økonomi.

Læs mere her.

The building of the new university hospital, thanks to a collaboration with Aalborg Utilities and Aalborg Portland, paved the way for a completely new symbiosis group in Aalborg. The companies, Aalborg Utilities and Aalborg Portland, joined forces on a sustainable alternative to the traditional cooling systems: They plan to use the constant cold water from Aalborg Portland’s limestone quarry to cool the hospital buildings. Cooling of the hospital is a vital step in developing district cooling systems in Aalborg, affording an opportunity to connect more companies to the system in the future.

Vi er med i udviklingen af en forretningsmodel for genbrug af tekstilrester fra Aalborg Teater. Vi bidrager med viden om produktionsforhold og udgifter og forventer også at skulle producere produktet, når og hvis det bliver til virkelighed.

Socialøkonomi og cirkulær bæredygtig økonomi er vores forretningsstrategi

Jeanne Debes, stifter og direktørSom socialøkonomisk virksomhed er vi vant til at tænke og arbejde bæredygtigt. Vi anvender rester og overskud i mange former til vores produkter og services, som vi sælger på markedsmæssige vilkår. Vores arbejdsressourcer består af borgere, der er nye i landet eller på anden vis har behov for udvikling af mestringsevne og tilpasning til arbejdsmarkedet efter individuelle forhold. Mangfoldighed, ligeværd og inklusion er vigtige nøgleord for os.

Hos Ornli’ by SEP Nord taler vi om socialøkonomi og cirkulær økonomi. Vi fokuserer på sammenhængen mellem ansvarlighed, miljøhensyn og bundlinje, og der er ingen grund til at trække skillelinjer mellem de tre begreber. Tværtimod.

Reparation, istandsættelse og genbrug indebærer et hav af arbejdsopgaver, der passer perfekt til vores socialøkonomiske virksomhed; vi beskæftiger mennesker, der ellers ville være i overhængende risiko for helt at glide ud af arbejdsmarkedet. Der ligger et stort uudnyttet jobpotentiale i samspillet mellem socialøkonomi og cirkulær økonomi.

Eksempel 1: Puder fra og til Gades Møbler

Eksempel 2: Smukfest-hatte af genanvendte materialer

Eksempel 3: PostNord keyhangers

Eksempel 4: Skindhynder af restlæder

Pakkeriet Hadsund, som er startet i 2021, er en iværksættervirksomhed, der bygger bro mellem det etablerede erhvervsliv og borgere, der kan og vil yde et meningsfuldt stykke arbejde under forhold, der sikrer, at opgaverne skaber værdi for både kunden og borgeren.

Mariagerfjord kommune står for at skulle lægge opgaven med at indsamle og klargøre EPS til genanvendelse ud til det private erhvervsliv. Det ville være et oplagt nyt forretningsområde for Pakkeriet, som lige nu beskæftiger et varierende antal flextidsansatte medarbejdere, som blandt andet samler, reparerer og pakker produkter for andre virksomheder. I samarbejde med BEWi undersøgte Pakkeriet, hvordan de ville kunne organisere og udføre indsamling, komprimering og videresalg af flamingo (EPS) i den rette kvalitet. Et nært samarbejde i værdikæden på denne måde sikrer et mere socialt bæredygtigt arbejdsmarked, samtidig med at så meget materiale som muligt indsamles og samtidig optimeres til genanvendelse hos BeWi.

Symbiosen undersøgte, hvordan EPS fra Mariagerfjord og Rebild Kommune samt fra private aktører i området kan danne grundlag for en ny afdeling hos Pakkeriet. På den måde kan der genanvendes EPS, som for nuværende ikke indsamles eller behandles korrekt, og det skaber en positiv miljøeffekt.

Pakkeriet Hadsund tilbyder lokal og socialt bæredygtig løsning af opgaver for erhvervsvirksomheder – det er både CSR og værdiskabende aktivitet samtidig; effektivt, fleksibelt og til tiden.

Virksomheden gør det muligt at samle, pakke, reparere eller udvikle tilpassede løsninger. Emballage fra virksomheder i nærområdet hentes og genbruges. Produkter, der skulle kasseres pga. produktionsfejl, repareres og tilpasses i værkstedet. Det sparer betydelige ressourcer i forhold til, hvis der skulle produceres og transporteres et nyt parti varer til kunden.

Frem for alt skaber Pakkeriet rammer der gør, at borgere, der har fysiske eller psykiske udfordringer, kan være på arbejdsmarkedet. Det skaber et mere rummeligt arbejdsmarked og bæredygtighed socialt. Når Pakkeriet løser en opgave, får kunden derfor styrket deres CSR-profil, hvilket kommer dem til gode i markedsføring og rapportering, samtidig med at det konkrete, lavpraktiske arbejde gør en forskel i de ansattes liv.

PlusBolig har i samarbejde med Titan Nedbrydning A/S arbejdet med brug af genbrugsmaterialer i byggeri. Dette har resulteret i udviklingen af et orangeri i genbrugsmaterialer.

Materialer fra nedrivning og renovering af PlusBoligs egne boliger kan således indgå cirkulært i opførelsen af smukke orangerier til glæde for PlusBoligs beboere.

Videnssymbiose i PlusBolig afd. 47

Renoveringen af PlusBolig afdeling 47 på Peter Bruuns Vej / Carl Rothes Vej / C.P. Holbølls Plads i Aalborg, har været omdrejningspunkt for et videnssamarbejde mellem virksomhederne Arne Andersen, Titan Nedbrydning og Anker Christensen. I forbindelse med projekt GRØN – Grønne Ressource-Økosystemer Nordjylland – samarbejdede virksomhederne ekstra meget om bæredygtighed og korrekt affaldssortering på byggepladsen, så mere affald kan genanvendes og genbruges.

Fremme biodiversitet i grønne områder

I PlusBolig arbejder vi på at udbrede biodiversitet i de grønne områder. Biodiversitet er afgørende for et velfungerende økosystem, med ren luft og vand til alle. Vi er i gang med at efteruddanne de medarbejdere, som passer de grønne områder. De får ny viden, forståelse og teknikker til omdannelse og vedligehold af mere naturlige grønne områder. Biodiversitet er derudover indarbejdet i PlusBoligs Hvidbog, som er en designmanual for nybyggeri og renovering. Hvidbogen indeholder krav og ønsker til fremtidige projekter og bidrager til at visioner og mål nås. PlusBoligs Bæredygtighedsvision er en del af Hvidbogen, som blandt andet sætter fokus på biodiversitet. Det er en folder og en rapport med målsætninger for bæredygtig udvikling, der giver sunde boliger for alle.

Læs mere her.

Port of Aalborg is part of a symbiosis, in which purified sand is utilised by the cement producer Aalborg Portland. The sand is derived from the periodic dredging of the Limfjord, which is necessary for ships to navigate the fjord. Since sand, combined with lime, is the primary raw material for the production of grey cement, the sand is used in Aalborg Portland’s cement production. Prior to this collaboration, the dredged sand was deposited in the sea. Quantities fluctuate throughout the year depending on weather conditions, but on average approx. 100,000 tonnes of sand are recycled annually.

Symbioses are an integral part of our sustainable business park and are incorporated into the development and design of both our own and our customers' companies.

Jesper Raakjær, Port of Aalborg Development and HR ManagerPort of Aalborg is a modern inland port with a 360-degree view, multimodal logistics solutions, and an unambiguous focus on supporting the realisation of Aalborg Municipality’s business and sustainability strategy. As Denmark’s largest inland port, Port of Aalborg’s development strategy also has a clear focus on the developing the surrounding business park, which has been designated as Aalborg’s future growth zone.

Sustainability is a focal point for the port’s activities, from which the role of industrial symbiosis facilitator emanates. Port of Aalborg supports green transition both locally and globally. In collaboration with a number of local actors that include Aalborg University, the municipal authorities, utilities, companies and business networks, determined efforts are being made to develop Green Hub Denmark and showcase Aalborg on the world stage as a leading sustainable industrial symbiosis.

In addition, we are actively working on the UN’s 17 Sustainable Development Goals. Internally, Port of Aalborg also reduced electricity consumption and CO2 emissions by approx. 40% from 2010 to 2018. Moreover, environmentally friendly cranes, electric bicycles and electric cars, light-controlled LED lighting outdoors and indoors, energy optimization of buildings, recycling of residual products, establishment of photovoltaic systems and cycle paths, etc. have been implemented.